Malo osungiramo zinthu zitatu-dimensional ndi gawo lofunikira pazantchito. Ili ndi zabwino zambiri monga kupulumutsa malo, kuchepetsa kuchuluka kwa anthu ogwira ntchito, kuthetsa zolakwika, kukonza makina osungira katundu ndi kasamalidwe, kuwongolera kasamalidwe ndi ogwira ntchito, kuchepetsa kutayika kwa zosungirako ndi zoyendera, kuchepetsa kubweza kwa ndalama zogwirira ntchito, ndikuwongolera magwiridwe antchito. Kuchita bwino, Panthawi imodzimodziyo, nyumba yosungiramo zinthu zodziwikiratu zomwe zimagwirizanitsidwa ndi makina oyendetsera makompyuta a fakitale komanso ogwirizana kwambiri ndi mzere wopanga ndi njira yofunikira kwambiri ya CIMS (Computer Integrated Manufacturing System) ndi FMS (njira yosinthika yopangira). Ilinso ndi dongosolo lomwe limasunga zokha ndikutulutsa zinthu popanda kuwongolera mwachindunji. Ndizopangidwa mwaukadaulo wapamwamba pakutukuka kwamakampani amakono, ndipo ndikofunikira kuti mabizinesi apititse patsogolo zokolola Kuchepetsa mtengo kumakhala ndi gawo lofunikira.

M'zaka zaposachedwa, ndikusintha kosalekeza kwa kupanga ndi kasamalidwe ka mabizinesi, mabizinesi ochulukirachulukira akuzindikira kuti kuwongolera ndi kulingalira kwadongosolo lazinthu ndizofunikira kwambiri pakukula kwamabizinesi. Stacker ndiye chida chofunikira kwambiri chonyamulira ndikuyika mu nyumba yosungiramo zinthu zitatu. Imatha kunyamula katundu kuchokera kumalo ena kupita kwina kudzera pamanja, kugwiritsa ntchito semi-automatic kapena kungoyendetsa kwathunthu. Ikhoza kusuntha mmbuyo ndi mtsogolo mumsewu wodzipangira wa mbali zitatu ndikusunga katunduyo pakhomo la msewu wolowera kumalo onyamula katundu; Kapena m'malo mwake, tulutsani katunduyo m'chipinda chonyamula katundu ndikuwanyamula kupita nawo njira yodutsako, ndiye kuti, stacker ndi njanji kapena trolley yopanda njira yokhala ndi zida zonyamulira. Stacker ili ndi injini yoyendetsa stacker kuti isunthe ndikukweza mphasa. Stacker ikapeza malo onyamula katundu, imatha kukankha kapena kukoka zigawo kapena mabokosi onyamula katundu kulowa kapena kutuluka muchoyikamo. The stacker ali ndi kachipangizo kuti azindikire kusuntha kopingasa kapena kukweza kutalika kuti azindikire malo ndi kutalika kwa malo onyamula katundu, Nthawi zina mutha kuwerenganso dzina la magawo omwe ali mumtsuko ndi zidziwitso zina zofunika.

Ndi chitukuko chaukadaulo waukadaulo wamakompyuta komanso nyumba yosungiramo zinthu zitatu, kugwiritsa ntchito stacker kumachulukirachulukira, luso laukadaulo likuyenda bwino, komanso kutalika kwake kukukulirakulira. Mpaka pano, kutalika kwa stacker kumatha kufika 40m. M'malo mwake, ngati sizikuletsedwa ndi kumangidwa kwa nyumba yosungiramo katundu ndi mtengo wake, kutalika kwa stacker kungakhale kopanda malire. Kuthamanga kwa ntchito ya stacker kumakhalanso bwino nthawi zonse. Pakali pano, yopingasa ntchito liwiro la stacker ndi 200m / mphindi (stacker ndi katundu wamng'ono wafika 300m / min), kukweza liwiro ndi 120m / mphindi, ndi telescopic liwiro la foloko ndi mpaka 50m. /mphindi.

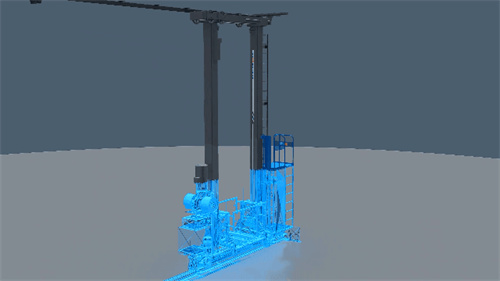

Kupanga kwa stacker

The stacker wapangidwa ndi chimango (chapamwamba mtengo, m'munsi mtengo ndi mzati), njira yopingasa yoyenda, njira yokweza, nsanja yonyamula katundu, mphanda ndi njira yoyendetsera magetsi. Zambiri ndi izi:

chimango

The chimango ndi chimango amakona anayi chimango wopangidwa chapamwamba mtengo, kumanzere ndi kumanja mizati ndi m'munsi mtengo, amene makamaka ntchito kubala. Pofuna kuwongolera kuyika kwa magawo ndi kuchepetsa kulemera kwa stacker, matabwa apamwamba ndi apansi amapangidwa ndi zitsulo zachitsulo, ndipo mizatiyo imapangidwa ndi zitsulo zazikulu. Kumtunda kwa mtanda kumaperekedwa ndi choyimitsa njanji yakumwamba ndi chotchinga, ndipo chopingasa chapansi chimaperekedwa ndi choyimitsa njanji.

Njira yogwiritsira ntchito

Makina othamanga ndi njira yoyendetsera kayendetsedwe kopingasa kwa stacker, yomwe nthawi zambiri imakhala ndi mota, coupling, brake, reducer ndi gudumu loyenda. Iwo akhoza kugawidwa mu nthaka akuthamanga mtundu, chapamwamba kuthamanga mtundu ndi wapakatikati kuthamanga mtundu malinga ndi malo osiyanasiyana akuthamanga limagwirira. Pamene mtundu wothamanga wapansi ukugwiritsidwa ntchito, mawilo anayi amafunika kuti ayendetse pamtunda wa monorail pansi. Pamwamba pa stacker amatsogoleredwa ndi mawilo awiri osakanikirana pamodzi ndi I-mtengo wokhazikika pamtengo wapamwamba. Mtsinje wakumtunda umalumikizidwa ndi mabawuti ndi mizati, ndipo mtengo wapansi umalumikizidwa ndi chitsulo chachitsulo ndi mbale yachitsulo. Makina oyendetsa oyendayenda, gudumu lagalimoto la master-slave, kabati yamagetsi, ndi zina zonse zayikidwapo. Mbali ziwiri za mtengo wapansi zilinso ndi zotchingira kuti ziteteze kuti stacker isapange mphamvu yogundana chifukwa chosawongolera mbali zonse ziwiri za ngalandeyo. Ngati stacker ikufunika kupindika, zosintha zina zitha kupangidwa panjanji yowongolera.

Makina okweza

Makina okweza ndi njira yomwe imapangitsa nsanja yonyamula katundu kuyenda molunjika. Nthawi zambiri amapangidwa ndi mota, brake, reducer, ng'oma kapena gudumu ndi magawo osinthika. Zomwe zimagwiritsidwa ntchito nthawi zambiri zimaphatikizanso chingwe chachitsulo chachitsulo ndi unyolo wokweza. Kuphatikiza pa chochepetsera giya wamba, chochepetsera giya ya nyongolotsi ndi pulaneti yochepetsera amagwiritsidwa ntchito chifukwa chakufunika kwa liwiro lalikulu. Zida zambiri zonyamulira unyolo zimayikidwa kumtunda ndipo nthawi zambiri zimakhala ndi ma counterweights kuti achepetse mphamvu yokweza. Kuti makina onyamulira akhale ocheperako, mota yokhala ndi brake imagwiritsidwa ntchito nthawi zambiri. Unyolo umalumikizidwa mokhazikika ndi mphasa kudzera pamagetsi pazanja. Chigawo chothandizira chokweza choyima ndi gawo. Mzerewu ndi bokosi la bokosi lomwe lili ndi anti distortion yoyamba, ndipo njanji yowongolera imayikidwa mbali zonse za mzere. Mzerewu ulinso ndi masiwichi apamwamba komanso otsika malire ndi zigawo zina.

Mfoloko

Amapangidwa makamaka ndi mota yochepetsera, sprocket, chipangizo cholumikizira unyolo, mbale ya foloko, njanji yosunthika, njanji yowongolera, mayendedwe odzigudubuza ndi zida zina zoyikira. Njira ya foloko ndi njira yoyendetsera kuti stacker ipeze katunduyo. Imayikidwa pampando wa stacker ndipo imatha kukulitsidwa mopingasa ndikubwezeredwa kuti itumize kapena kutulutsa katunduyo mbali ziwiri za gridi yonyamula katundu. Nthawi zambiri, mafoloko amagawidwa m'mafoloko amodzi, mafoloko awiri kapena mafoloko angapo malinga ndi kuchuluka kwa mafoloko, ndipo mafoloko ambiri amagwiritsidwa ntchito kwambiri poika katundu wapadera. Mafolokowo amakhala ndi mafoloko a matelesikopu okhala ndi magawo atatu, omwe amakhala ndi foloko yapamwamba, foloko yapakatikati, mphanda wam'munsi ndi singano yokhala ndi ntchito yowongolera, kuti muchepetse m'lifupi mwamsewu ndikupangitsa kuti ikhale ndi maulendo a telescopic okwanira. Foloko imatha kugawidwa m'mitundu iwiri molingana ndi kapangidwe kake: gear rack mode ndi sprocket chain mode. Mfundo ya telescoping ya foloko ndi yakuti foloko ya m'munsi imayikidwa pa pallet, foloko yapakati imayendetsedwa ndi bar ya gear kapena sprocket bar kuti isunthe kumanzere kapena kumanja kuchokera kutsogolo kwa mphanda wapansi ndi pafupifupi theka la kutalika kwake, ndipo foloko yakumtunda imafikira kumanzere kapena kumanja kuchokera pakati pa mphanda wapakati ndi utali wotalikirapo pang'ono kuposa theka la utali wake womwe. Foloko yapamwamba imayendetsedwa ndi maunyolo awiri odzigudubuza kapena zingwe za waya. Mapeto amodzi a unyolo kapena chingwe cha waya amakhazikika pa foloko yapansi kapena pallet, ndipo mapeto ena amaikidwa pa foloko yapamwamba.

Makina okweza ndi mphasa

Makina onyamulira makamaka amapangidwa ndi kukweza mota (kuphatikiza chochepetsera), drive sprocket, drive chain, sprocket iwiri, unyolo wokweza ndi idler sprocket. Unyolo wokweza ndi unyolo wa mizere iwiri yokhala ndi chitetezo chachikulu kuposa 5. Amapanga chotsekeka chotsekedwa ndi sprocket yopanda pake pa pallet ndi matabwa apamwamba ndi apansi. Pamene galimoto yonyamulira imayendetsa gudumu la maunyolo awiri kuti azungulire muzitsulo zoyendetsa galimoto, chingwe chonyamulira chidzasuntha, motero kuyendetsa nsanja yokweza (kuphatikizapo mafoloko ndi katundu) kuti idzuke ndi kugwa. Galimoto yonyamula imayang'aniridwa ndi kutembenuka kwafupipafupi kwa PLC kuti apewe kupsinjika kwambiri pa unyolo wokweza kumayambiriro kokweza ndikuyimitsa. Malo onyamula katundu amapangidwa makamaka ndi mbale zachitsulo zophwanyika komanso zowotcherera, zomwe zimagwiritsidwa ntchito kwambiri poyika mafoloko ndi zida zina zodzitetezera. Pofuna kuonetsetsa kuti mphasa ikuyenda bwino, mawilo 4 owongolera ndi mawilo 2 apamwamba pamzake amayikidwa mbali iliyonse ya mphasa.

Zida zamagetsi ndi zowongolera

Zimaphatikizapo kuyendetsa magetsi, kutumiza ma signal ndi stacker control. Stacker imatengera chingwe cholumikizira chotsetsereka chamagetsi; Popeza magetsi akutsetsereka kukhudzana mzere chonyamulira kulankhulana n'zosavuta kusokonezedwa ndi kuunjikana mphamvu, ndi infuraredi kulankhulana mode ndi zabwino odana kusokoneza anatengera kusinthanitsa zambiri ndi kompyuta ndi zipangizo zina zosungiramo katundu. Makhalidwe ogwirira ntchito a stacker ndikuti ayenera kuyikidwa bwino ndikuyankhidwa, apo ayi idzatenga katundu wolakwika, kuwononga katundu ndi mashelufu, ndikuwononga stacker yokha pazochitika zazikulu. Kuwongolera malo a stacker kumatengera njira yozindikiritsa ma adilesi, ndipo chowunikira cha laser chimagwiritsidwa ntchito kudziwa malo omwe ali ndi stacker poyesa mtunda kuchokera pa stacker kupita kumalo oyambira ndikuyerekeza zomwe zasungidwa mu PLC pasadakhale. Mtengo wake ndi wokwera, koma kudalirika ndikwambiri.

Chipangizo choteteza chitetezo

Stacker ndi mtundu wamakina onyamulira, omwe amafunikira kuthamanga kwambiri pamakina apamwamba komanso opapatiza. Pofuna kuonetsetsa chitetezo cha ogwira ntchito ndi zida, stacker iyenera kukhala ndi zida zonse zotetezera chitetezo cha hardware ndi mapulogalamu, ndipo njira zingapo zolumikizirana ndi zotetezera ziyenera kuchitidwa pamagetsi. Zida zazikulu zodzitchinjiriza zachitetezo zimaphatikizira chitetezo chomaliza, chitetezo cholumikizirana, kuwongolera koyang'anira malo, chitetezo chazingwe zonyamula katundu, chitetezo chozimitsa, ndi zina.

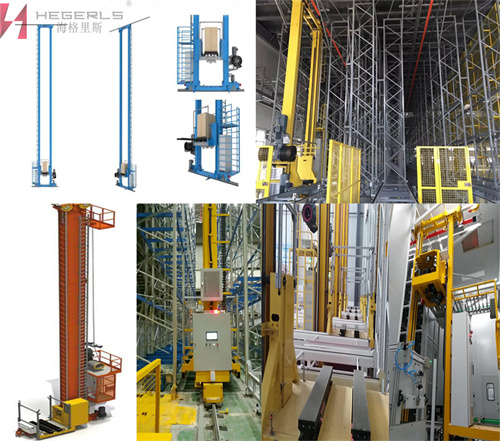

Kutsimikiza kwa mawonekedwe a stacker: pali mitundu yosiyanasiyana ya stacker, kuphatikizapo monorail tunnel stacker, double njanji stacker, rotary tunnel stacker, single column stacker, double column stacker, etc.

Kutsimikiza kwa liwiro la stacker: molingana ndi zofunikira zoyendetsera nyumba yosungiramo katundu, werengerani liwiro lopingasa, liwiro lokweza ndi liwiro la foloko la stacker.

Magawo ena ndi kasinthidwe: mawonekedwe oyika ndi njira yolumikizirana ya stacker imasankhidwa malinga ndi malo osungiramo zinthu komanso zofunikira za wogwiritsa ntchito. Kukonzekera kwa stacker kungakhale kokwera kapena kochepa, malingana ndi momwe zinthu zilili.

Kugwiritsa ntchito makina osungiramo zinthu zitatu-dimensional

* Samalani kuti malo opangira opaleshoni azikhala oyera komanso oyera, ndikutsuka fumbi, mafuta ndi zina tsiku lililonse.

* Popeza chophimba chokhudza ndi zida zina zamagetsi pagawo la opaleshoni zimawonongeka mosavuta ndi chinyezi, chonde zisungeni zoyera.

*Mukamatsuka pagawo lopangira opaleshoni, tikulimbikitsidwa kugwiritsa ntchito nsalu yonyowa kuti mupukute, ndipo samalani kuti musagwiritse ntchito zoyeretsa zowononga monga mafuta.

*Mukasuntha AGV, galimotoyo iyenera kukwezedwa kaye. Pamene galimoto ikulephera kukwezedwa pazifukwa zina, mphamvu ya AGV iyenera kuzimitsidwa. Ndizoletsedwa kusuntha AGV pamene galimoto yatsegulidwa ndipo galimotoyo siinanyamulidwe.

*Pamene AGV ikufunika kuyimitsidwa pakagwa ngozi, batani lazadzidzi lidzagwiritsidwa ntchito. Ndizoletsedwa kugwiritsa ntchito kukoka kapena njira zina zosokoneza kukakamiza trolley ya AGV kuyimitsa.

*Ndizoletsedwa kuyika chilichonse pa opareshoni panel.

Kukonza kwatsiku ndi tsiku kwa stacker yosungiramo zinthu zitatu-dimensional

* Konzani zosintha kapena zakunja mu stacker ndi misewu.

* Onani ngati pali kutayikira kwamafuta pamalo oyendetsa, okwera ndi mphanda.

*Yang'anani momwe chingwechi chilili.

* Dziwani mavalidwe a njanji yowongolera ndi gudumu lowongolera pazanja.

* Tsukani maso / masensa amagetsi oyikidwa pa stacker.

* Kuyesa kwamagetsi kwa diso lamagetsi / sensor yoyikidwa pa stacker.

* Yang'anani kuyendetsa ndi kuyendetsa magudumu (kuvala).

* Onani zowonjezera ndikuwona ngati gudumu lothandizira lawonongeka.

* Onetsetsani kuti palibe mng'alu pa malo owotcherera a kulumikizana kwa ndime ndi kulumikiza bawuti.

*Yang'anani malo opingasa a lamba wa mano.

* Onani kuyenda kwa stacker.

* Yang'anani m'maso ntchito yopenta ya stacker.

Ndi chitukuko cha kupanga mafakitale amakono, m'nyumba yosungiramo zinthu zitatu, kugwiritsa ntchito stacker kudzakhala kokulirapo, makamaka kumagwiritsidwa ntchito popanga makina, kupanga magalimoto, mafakitale a nsalu, njanji, fodya, mankhwala ndi mafakitale ena, chifukwa mafakitale awa adzakhala abwino kwambiri ntchito yosungiramo zodziwikiratu posungirako. Hagerls ndi bizinesi yayikulu yomwe ikuyang'ana kwambiri yankho, kapangidwe, kupanga ndi kukhazikitsa ntchito zanzeru zosungiramo zinthu komanso zida zanzeru zothandizira zida zamagetsi. Itha kupatsa makasitomala ndi stacker imodzi, stacker yapawiri, stacker yotembenuza, stacker yowonjezera iwiri ndi bin stacker ndi mitundu ina ya zipangizo. Ikhoza kusintha mitundu yosiyanasiyana ya zida za stacker malinga ndi zinthu zosiyanasiyana, mosasamala kanthu za kukula ndi kulemera kwake.

Nthawi yotumiza: Aug-18-2022